Products

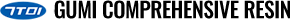

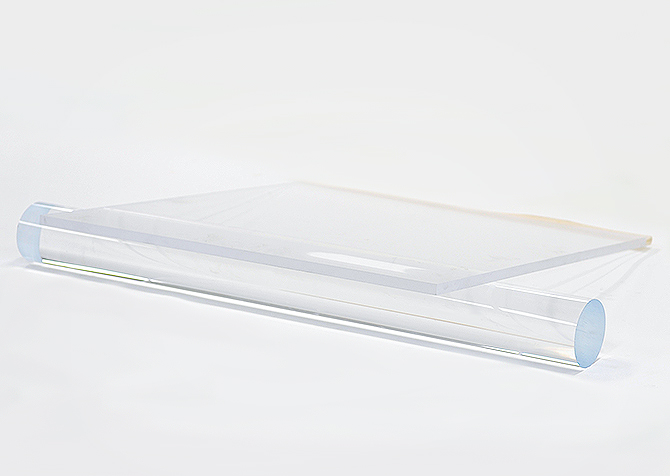

ACRYL

Overview

Transparency that penetrates about 90% of light, excellent colorability that allows various color combinations, and does not tarnish when exposed to the outdoors.

Characteristic

Excellent transparency and excellent weather resistance that does not tarnish under long-term direct sunlight

Lightweight, but stronger impact resistance than tempered glass

Excellent molding adhesion processability

Resistant to water, salt, weak acids, but weak to alkali and organic solvents

Excellent molding adhesion processability / excellent bonding

Purpose

For various signboards, nameplates, building ceilings, exterior walls, soundproof walls, display stands, aquariums, interiors

Types and colors

Transparent / Blue / Black / Brown / Red / Green / Smog / Various colors

Rod Material

Specifications (Unit mm)| Outer diameter | length | 2⌀ ~ 120⌀ | 1,000 |

|---|

Pipe

Specifications (Unit mm)| thickness | Outer diameter | length | 1T ~ 10T | 5⌀~ 600⌀ | 1,000 / 2,000 |

|---|

Board Material

| thickness | width x length | 1T ~ 70T | 3x6 / 1x2 / 4x8 |

|---|

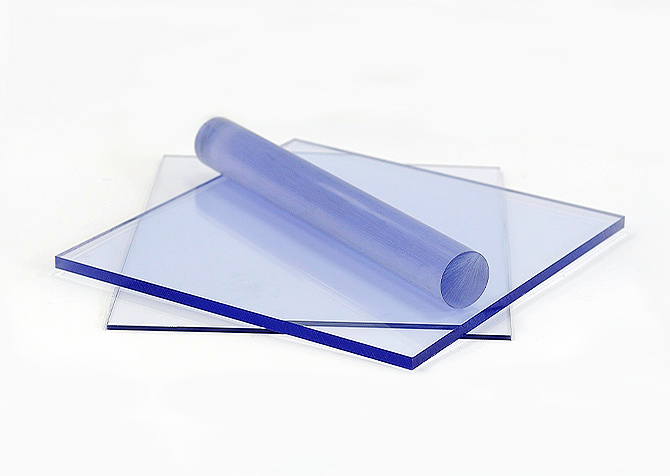

PC

Overview

It has impact strength of about 150 times more than tempered glass and about 50 times than acrylic, It is used as complement and substitute for ordinary plate glass, and is used as building material.

Characteristic

Excellent impact strength It is used in buildings that are difficult to implement with glass due to its low weight, or when working with lightweight, high-strength and transparent materials, and is used as a substitute for glass.

Excellent light transmittance, excellent UV protection ability With transmittance of 85% to 90%, the functions of high transmittance and UV protection function provide excellent functionality and appearance.

Essential parts for semiconductor and electronics equipment industry Essential materials for clean room and profile manufacturing

For food and pharmaceutical packaging It contains relatively few harmful ingredients, to use as packaging for food or medicine

Used in various industries of flame retardant polycarbonate (V0) For commonly used PCs, it is rated V2 and is flame retardant PC. i.e. self-extinguishing PCs are rated V0 grade.

Excellent bonding

Purpose

For new construction materials, display equipment covers, soundproof walls, rain screen, splash barriers, greenhouses, barns

Types and colors

PC (Basic) / PC Antistatic / PC VO / PC GF30

Transparent / Black / Light Green / Dark Green / Smog / Yellow / Brown / Blue / Optical acid (for lighting) / Embossed

Rod Material

Specifications (Unit mm)| Outer diameter | length | 6⌀ ~ 150⌀ | 1,000 |

|---|

Roll

Specifications (Unit mm)| thickness | width | length | 03t ~ 5t | 900/ 1000 / 1200 /1500 | ROLL |

|---|

Board Material

Specifications (Unit mm)| thickness | widthxlength | 1T ~ 70T | 1x2/ 4x8 / 5x10 |

|---|

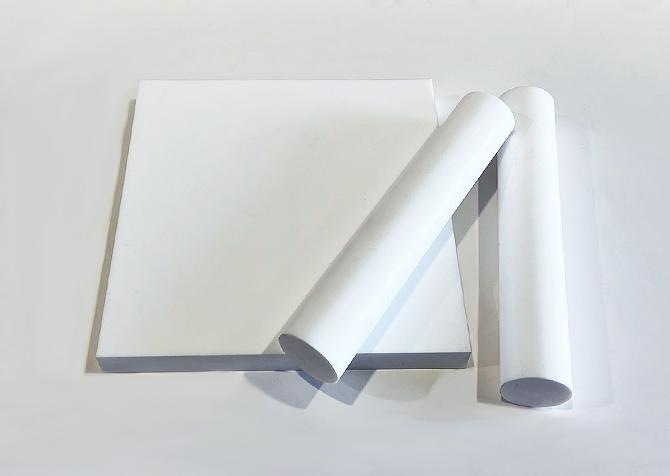

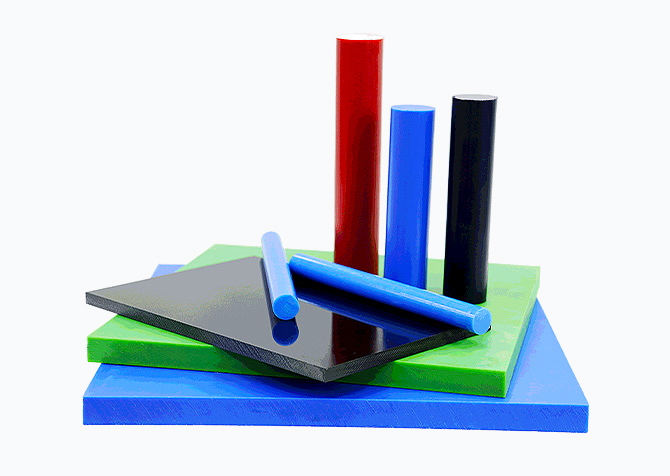

POM

Overview

As representative engineering plastic, it is mainly used where precision is required for various mechanical equipments

Characteristic

Excellent mechanical properties

Excellent creep resistance over wide temperature range

Highest friction resistance among thermoplastic resins

Excellent chemical resistance

Purpose

For bearings, rollers. pumps, gear parts, precision machinery parts, textile industry parts, insulation products of electrical and electronic semiconductors

Types and colors

POM-C: White, Black / POM-H: White, Black / BESTAL-G: Green / POM ESD: Off-white, Black

Rod Material

Specifications (Unit mm)| Outer diameter | length | 3⌀ ~ 250⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 5t~300t | 600 / 1,000 / 1,200 | 1,200 / 2,000 / 2,400 |

|---|

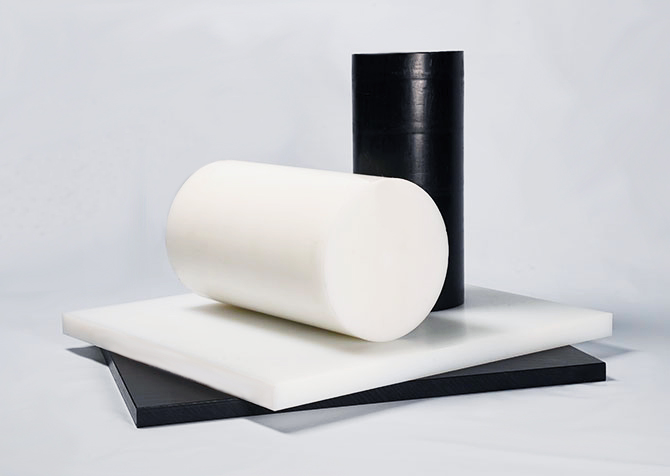

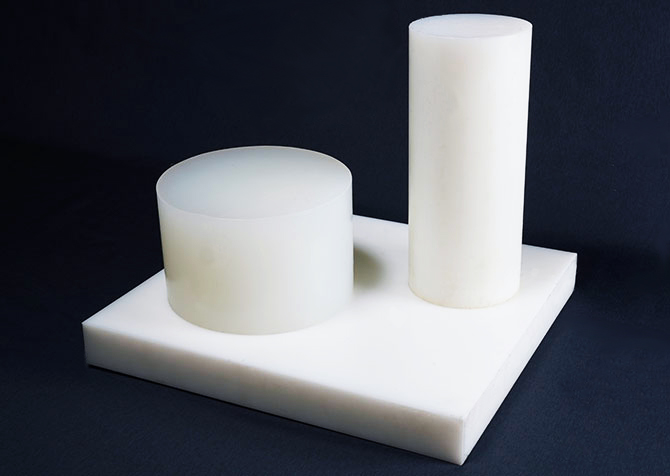

MC

Overview

In addition to POM (acetal), the most commonly used engineering plastics

Characteristic

Relatively high tensile strength

Excellent abrasion resistance and durability

Excellent self-lubricating properties

High surface hardness

Purpose

For ship building, steel, metal machinery industry, PALLET for product protection, food container, electronics, mechanical equipment

Types and colors

MC NYLON : MC901 , MC907

MC501 R2, R6, R9 (blue, off-white, black, red, yellow, etc.)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 500⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 5t~300t | 600 ~ 1200 | 1200 ~ 2400 |

|---|

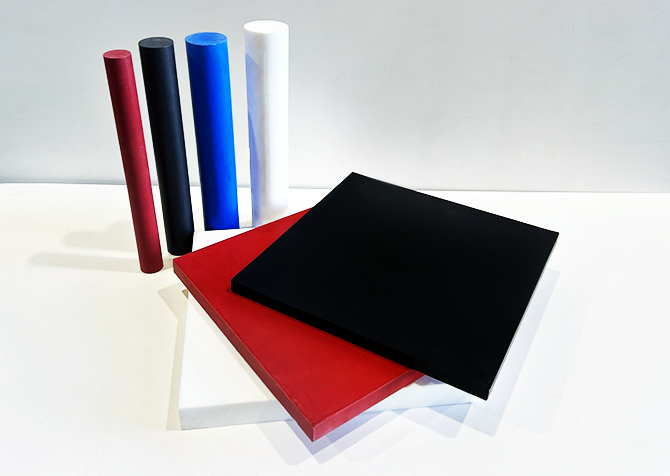

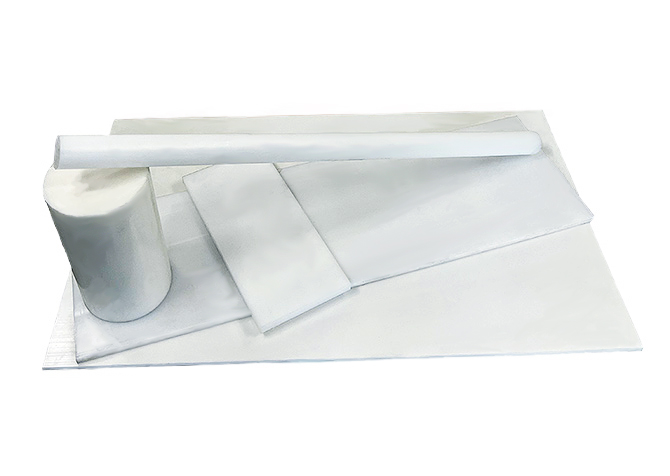

PTFE

Overview

As a representative fluorine plastic resins with the greatest demand, which is resistant to surface contamination, acid-resistant, and resistant to a wide range of chemicals.

Characteristic

Typical continuous use temperature of 260°C

Excellent chemical resistance, cold resistance, heat resistance

Low friction coefficient and excellent self-lubrication

Excellent weather resistance, non-adhesive

Continuous use temperature -180°C to +260°C

Purpose

For components related to semiconductor equipment such as gaskets, bellows, etc. and parts for grafting, tapes, films, connectors, etc. Electrical insulation, remote condo mirrors, etc. automobile parts

Types and colors

PTFE (base) / PTFE GLASS (fiberglass) / PTFE CARBON (carbon) / PTFE RULON / PTFE BRONZE

Rod Material

Specifications (Unit mm)| Outer diameter | length | 5⌀ ~ 120⌀ | 1,000 |

|---|

Pipe

Specifications (Unit mm)| Outer diameter | Internal diameter | length | 30 ~ 180(there is a gap) | 20 ~ 175 | 100 / 150 / 300 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 0.3T ~ 200T | 300 / 1,000 / 1,200 | 300 / 1,000 / 1,200 |

|---|

PVC

Overview

As typical fire-resistant material, it is inexpensive and commonly used engineering plastic. It is also called polyvinyl chloride, vinyl chloride resin. (PVC raw material is pressed and foamed for fomax)

Characteristic

Generally available from -15°C to +60°C

Excellent for adhesion or welding

Excellent heat resistance

Excellent machinability

Excellent flame retardancy

Excellent electrical insulation

Excellent in acids

Purpose

For semiconductor inspection equipment, chemical tanks, exhaust ducts, flooring, work racks, automotive interior materials

Plating Line / Anodizing Line

Types and colors

Rigid PVC / Soft PVC

PVC : Ivory / Grey / Transparent / Black

C-PVC / HT-PVC / U-PVC

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 300⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1T ~ 200T | 1,000 / 1,200 | 1000 / 3000 |

|---|

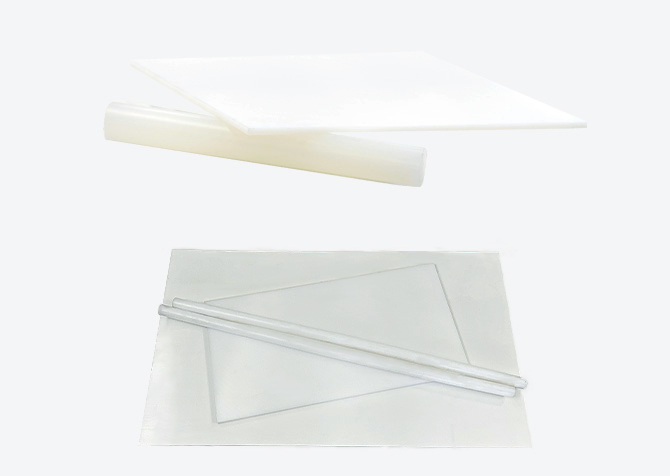

UHMW PE (GUR)

Overview

Ultra-high molecular weight polyethylene with average molecular weight of more than about 3 million, and has better overall physical properties are superior to HDPE.

Characteristic

Generally available from -100°C to max. 80°C

Excellent mechanical strength and tensile strength

Excellent chemical resistance, easy painting and adhesion

Excellent self-extinguishing properties

Suitable for use of materials in accordance with the Food Sanitation Act

Purpose

For components for dental industry, parts for brush industry, pumps, valves, seals, piping, etc., and parts for food equipment guides, hoppers, etc.

Kitchen cutting board / sushi tray

Types and colors

UHMW-PE : White/Black/Green

UHMW-PE ESD

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 350⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1T ~ 200T | 1,000 / 1,200 | 1000 / 3000 |

|---|

PEEK

Overview

As one of the representative high-performance engineering plastics, it is a material with high heat resistance, dimensional stability and excellent chemical resistance

Characteristic

Continuous use temperature 260°C

Excellent mechanical properties over wide temperature range

Excellent chemical resistance, electrical properties and weather resistance

Excellent flame retardancy (VO rating)

FDA Approval

Purpose

For major machinery components in defense industry, parts for aviationm and space industry, chemical facilities, semiconductor equipment parts, equipment parts for energy industry

Types and colors

PEEK (basic) / PEEK GF30 (30% glass fiber) / PEEK CF30 (30% carbon fiber) / PEEK HPV (high pressure, high speed specialized) / PEEK ESD (antistatic)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 3⌀ ~ 200⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1T ~ 60T | 610 ~ 1,000 | 2,000 |

|---|

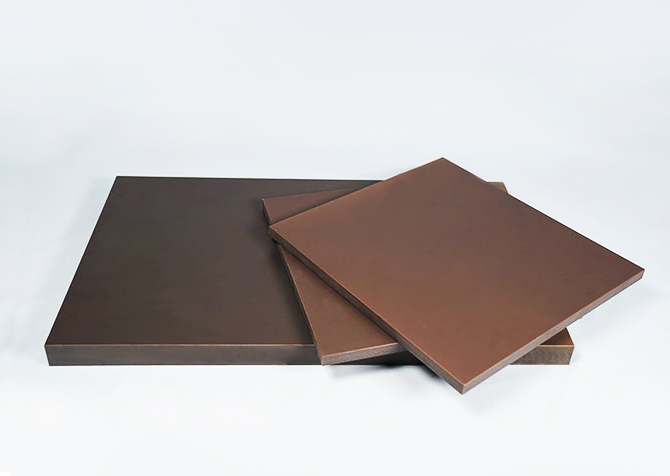

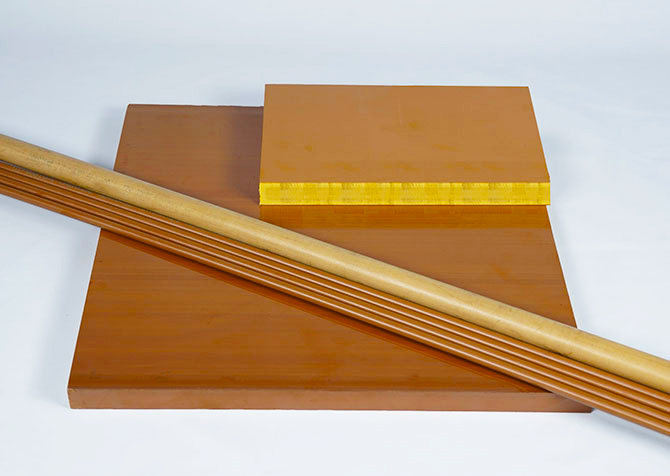

BAKELITE

Overview

As starting material of engineering plastics, it is used in various industries such as insulators and insulation.

Characteristic

Excellent electrical insulation, chemical resistance

Excellent flexural strength, heat resistance

Relatively good inner creep resistance

Purpose

For components of aircraft, railways, electrical, electronic, machinery, ships, laminated plates, electrical insulation plates, circuit boards and jigs

PCB board applications

Types and colors

G-bakelite (basic) / Po-bakelite (with cotton cloth) / Sepo-bakelite (with fine cotton cloth) / Antistatic bakelite / Super heat-resistant bakelite (continuous use temperature above 300°C)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 100⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 0.5T ~ 60T | 1,000 / 2,000 | 1,000 / 2,000 / 2,400 |

|---|

UNILATE

Overview

High-performance engineering plastic pressed after composite extrusion molding with with heating and laminating PET as main raw material filling glass fiber, inorganic filler, etc.

Characteristic

Excellent mechanical strength and heat resistance

Excellent electrical properties, dimensional stability, machinability

Continuous use temperature up to 120°C

Purpose

For test sockets in semiconductor industry, conveyor parts in food industry, various battery parts, wear pads, workbenches, guide wheels in energy industry

Types and colors

UNILATE PC (basic) / UNILATE NC (flame retardant) / UNILATE SC (antistatic) / UNILATE CV (conductive)

Board Material

Specifications (Unit mm)| Outer diameter | length | length | 0.5T ~ 55T | 1,000 | 1,000 |

|---|

PBI

Overview

It is called celazole that can be used at extremely high temperatures, and is the most heat-resistant material among engineering plastics in existence.

Characteristic

Continuous use temperature 340°C

Excellent heat resistance, excellent mechanical strength

Extremely abrasion resistant and withstands very high loads

Excellent resistance to high-energy radiation

Excellent electrical insulation

Plastics that can replace metal

Purpose

Mainly used in semiconductor display vacuum equipment parts, high temperature insulation bushings, aircraft engine electrical connector bushings and valves, pumps, piping, etc. in chemical industry, and nuclear electronic components, fuel cells, etc. in energy industry

Types and colors

PBI (basic) / PBI CF (carbon fiber) / PBI ESD (antistatic)

Board Material

Specifications (Unit mm)| thickness | width | length | 10T ~50T | 300 | 300 |

|---|

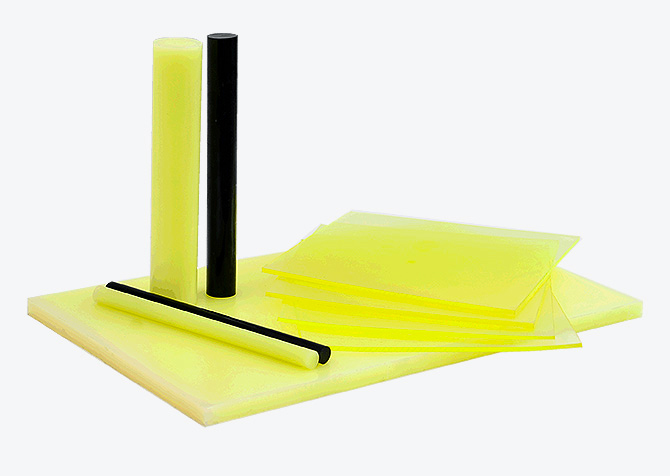

URETHAN

Overview

It is well resistant to chemicals and is used in electrical insulators, structural materials, insulation, etc., and used as substitute for industrial rubber because of its high elasticity, and for the higher of hardness, it is more used for rollers, etc., and for the lower of hardness, more used for cushioning materials, etc.

Characteristic

Better friction wear than rubber

Can be produced in various hardness (low hardness, normal hardness, high hardness)

Excellent abrasion resistance, vibration absorption, sound absorption

Excellent flexible and chemical resistance

Excellent electrical insulation

Wide operating temperature (-40°C to 90°C)

Purpose

For molding and extrusion products of various hardness, packing, rollers, shoe bottoms, anti-slip coatings, use of urethane rods, plate PUs, etc., and for industrial use, artificial leather, cushioning materials, memory foam, filters, etc.

Guide roller / B.4-T

Types and colors

Antistatic urethane / Soft urethane / Hard urethane / Fluorescent (yellow)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 600⌀ | 300 / 600 / 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 0.5T ~ 100T | 300 / 1,000 | 300 / 1,000 / 3,000 |

|---|

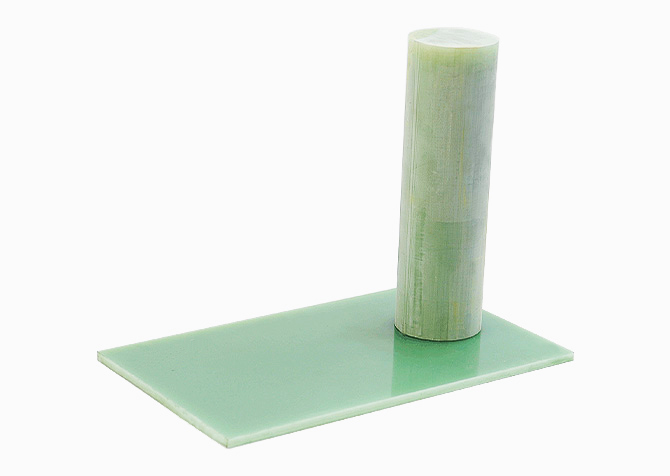

EPOXY

Overview

As a representative type of thermosetting resin, it is the most commonly used material mainly for electrical insulation, etc.

Characteristic

Less specific gravity than metal, but excellent strength

Excellent mechanical strength, dimensional stability and electrical insulation

Good formability by excellent machinability

Excellent chemical resistance

Used in various industries

Purpose

For insulation parts in semiconductor industry, electronic substrate parts, etc., and nuclear fusion equipment parts in energy industry, and transformer switch parts, etc., in electrical industry, and gears, bushing parts, etc. that require precision

PCB board applications

Types and colors

G10 (typical) / G11 (heat-resistant) / ESD EPOXY (antistatic)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 100⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1T ~ 5T | 1,000 / 1,200 | 1,200 / 2,400 |

|---|

PE

Overview

Called polyethylene, it is resistant to acids and alkalis, and is the most common plastic in everyday life.

Characteristic

Excellent corrosion resistance, volatility resistance

Excellent electrical insulation, abrasion resistance

Excellent impact strength at low temperatures

Excellent weldability

Purpose

For components of wastewater industry, conveyor screws, disc filters, etc., and food industry parts, etc.

Types and colors

HDPE / LDPE

UHMW-PE / Borotron-PE (Boron PE)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 350⌀ | 1,000 / 3,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1T ~ 200 | 1,000 / 1,200 | 1,200 / 3,000 |

|---|

PP

Overview

Along with PE, it is universally used general-purpose plastics in daily life in most industries

Characteristic

Excellent chemical resistance, excellent chemical resistance

Light tensile strength, high surface strength

Cheaper than other types of engineering plastic materials

Excellent weldability and fusibility

Excellent in acids

Excellent heat resistance

Purpose

For components pump valve parts in wastewater industry, and conveyor screws, etc., and food industry parts, etc.

Industrial Chemical Piping Applications

Types and colors

PP-H / PP-C / PP-R

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 350⌀ | 1,000 / 3,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1T ~ 200 | 1,000 / 1,200 | 1,000/ 3,000 |

|---|

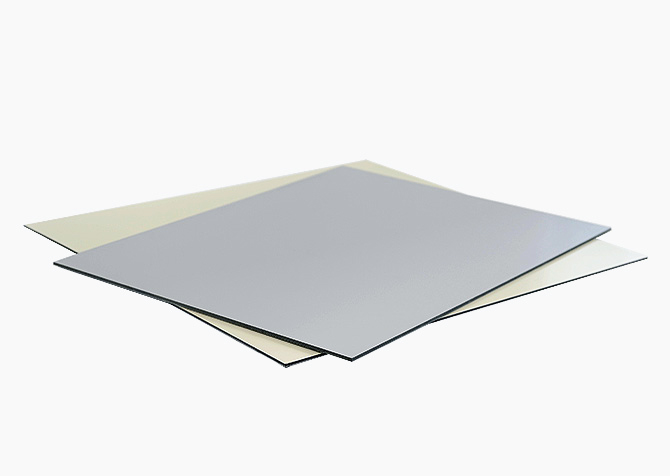

AL

Overview

It is a material made of two layers of aluminum coil bonded with PE or FR at high temperature, also known as aluminum-plastic laminated composite plate.

Characteristic

The core material is very light because it is made of resin

Can produce non-combustible panels with added non-flammability

Excellent stability against temperature changes

Excellent impact resistance, excellent smoothness, excellent constructability

Purpose

For buildings requiring insulation and sound insulation, display and signboards, interior wall finishing and columns such as furniture and doors, tunnels, interior and columns of subway stations, interior and exterior materials for new construction and remodeling of buildings

Types and colors

Ivory / Black / Silver / White

General AL / Antistatic AL / Quasi-non-combustible AL

Board Material

Specifications (Unit mm)| thickness | width | length | 2T ~ 5T | 1,000 / 1,200 | 1,200/2,400 |

|---|

PCTFE

Overview

It is a material with excellent mechanical properties and chemical resistance among fluorine plastic resins, and has better performance than Teflon.

Characteristic

Excellent pharmaceutical resistance, excellent chemical resistance (Excellent resistance to acids, alkalis, mixed acids and oxidizing agents)

Excellent dimensional stability, excellent impact resistance

Better compressive strength than Teflon at low temperatures below -80°C

Purpose

For valves for semiconductors, gaskets, pharmaceutical transport packs and medical packaging films, electrical components that require heat resistance in electrical industry

Rod Material

Specifications (Unit mm)| Outer diameter | length | 5⌀ ~ 300⌀ | 300 ~ 3,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 5T ~ 60T | 300 / 500 / 1000 | 300 / 500 / 1000 |

|---|

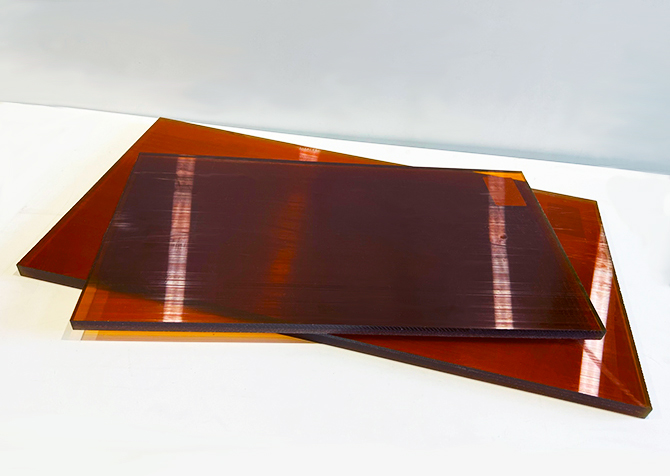

PI

Overview

First developed by DuPont in the United States, it is also called polyimide or vespel, a highly functional material made of anhydrides of aromatic diamine and aromatic tetra carbonic acid 2.

Characteristic

Excellent super heat resistance, excellent chemical resistance

Excellent machinability, excellent electrical insulation

Excellent abrasion resistance, excellent inner creep resistance

Excellent flame retardancy (continuous use temperature 280°C)

Plasma and radiation resistance

Purpose

For mechanical parts used at cryogenic temperatures, essential parts for aerospace and aviation industry, mechanical equipment films, insulation and insulation parts, piston rings, gears

Types and colors

Transparent, black, amber, brown, black-purple

General PI / Carbon Fiber PI / Molybdenum PI

Rod Material

Specifications (Unit mm)| Outer diameter | length | 6.3⌀ / 9.5⌀ / 11.1⌀ / 12.7⌀ / 15.8⌀ / 19⌀ / 25.4⌀ / 31.7⌀ / 38.1⌀ / 50.8⌀ / 63.5⌀ / 82.5⌀ / 107.9⌀ | 102 / 228 / 241 / 300 / 685 / 965 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1.6t, 3.2t, 4.8t, 6.4t, 12.7t, 25.4t, 38.1t, 50.8t | 127 / 254 | 127 / 254 |

|---|

ABS

Overview

It is a material made by mixing a total of three components of Acrylonitrile + Butadiene + Styrene plastic with excellent secondary processability such as injection molding and extrusion molding and coloring

Characteristic

Excellent impact resistance (high impact strength at low temperature)

Excellent dimensional stability, excellent bonding, excellent solubility

Excellent inner creep resistance

Purpose

For metal replacements for industrial products such as automobile parts, electric machinery, etc., wooden goods use, covers of mobile phones and laptops, and MOCK-UP are mainly used

Aquarium

Types and colors

Off-white / Black (NAT / BLK)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 6⌀ ~ 200⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 1T ~ 200T | 610 / 1,200 | 1,000 / 1,200 / 1,800 / 2,400 |

|---|

PET

Overview

It is classified as P-PET used in industrial parts because of its high transparency, including A-PET and G-PET, which are often used in food containers, disposable items and covers with high wear resistance, processability and compressive strength

Characteristic

Excellent inner creep resistance, excellent adhesive weldability

Recycled more compared to other plastics

Excellent mechanical strength, excellent electrical insulation

Excellent chemical resistance to acids

Purpose

For mineral water bottles, juice bottles, ionization bottles, etc. in food industry (A-PET) / Lithium-ion battery guides and cases in electrical and electronic industry (P-PET)

Medical device covers, functional parts, etc. in medical industry (A-PET) / Gear and slicing parts in industrial machinery industry (P-PET)

Types and colors

Transparent / White / Black

PET-P (Natural) / PET Tx (Wear Resistant) / PET ESD (Antistatic)

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 200⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 0.5T ~ 100T | 600 / 1,000 | 1,200 / 2,000 |

|---|

PEI(Ultem)

Overview

It is high-strength and heat-resistant engineering plastic of thermoplastic developed by GE Corporation of the United States, called "Ultem" with excellent electrical insulation properties

Characteristic

High operating temperature and machine strength

Excellent inner creep resistance, excellent weather resistance

Excellent self-extinguishing, stress cracking properties

Excellent resistance to pharmaceutical chemicals such as acids and alkalis and friction

Excellent radiation resistance

Purpose

For electrical equipment parts in electrical industry, parts required by heat resistance and anti-radiation wire in medical industry, metal replacement parts, insulating sleeves, important parts in aviation industry, and vehicle parts in automotive industry

Types and colors

Translucent Brown/Yellow

NAT (Ultem 1000) : Natural grade / GF30 (Ultem 2300) : GF30% added / Antistatic

Rod Material

Specifications (Unit mm)| Outer diameter | length | 6⌀ ~ 150⌀ | 1,000 ~ 3,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 6T ~ 100T | 610 | 1,000 ~ 3,000 |

|---|

PVDF

Overview

Compared with other fluorine plastic resins, it exhibits the most outstanding mechanical strength due to its high crystallinity with excellent chemical resistance, thermal and electrical properties.

Characteristic

Excellent mechanical strength, excellent chemical resistance

Continuous use temperature 150°C

Excellent weather resistance, excellent chemical resistance

UV resistant (UV), excellent abrasion resistance

Purpose

For valves, pumps, etc. in electrical and electronic industry, important parts in chemical industry, surgical equipment parts in pharmaceutical industry, important parts in semiconductor equipment industry, etc.

Types and colors

PVDF NAT / PVDF ESD

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 150⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 10T ~ 100T | 620 / 1,000 | 1,000 ~ 2,000 |

|---|

PPS

Overview

Compared with PEEK, it is similar engineering plastic in nature, but are more economical widely used in semiconductor and display industries.

Characteristic

Excellent chemical resistance to alkalis and acids

Continuous use temperature up to 220°C

Excellent dimensional stability by low coefficient of thermal expansion

Excellent electrical properties, low water absorption

Excellent flame retardancy

Purpose

For semiconductor, display of each manufacturing line equipment parts, test sockets, nuclear industry parts, aircraft industry equipment parts, pipes, pumps, valve parts, etc.

Types and colors

PPS NAT / PPS GF40 / PPS ESD

Rod Material

Specifications (Unit mm)| Outer diameter | length | 10⌀ ~ 100⌀ | 1,000 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 5t~300t | 600 / 1,000 / 1,200 | 1,200 / 2,000 / 2,400 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 10T ~ 50T | 620 | 1,000 |

|---|

PAI

Overview

It is one of the high functional engineering plastics with excellent heat resistance and high dimensional stability, and is used in various industrial groups such as test sockets and bearings

Characteristic

Excellent mechanical strength, excellent dimensional stability

Excellent chemical resistance, excellent processability

Excellent tensile strength and excellent compressive strength

High heat deformation temperature

Excellent strength and rigidity at high temperatures

Continuous use temperature up to 260°C

Purpose

For test sockets and insulation in semiconductor industry, fasteners in aviation industry, compressor parts and pump parts in gas industry, bearing parts in automotive industry, etc.

Types and colors

PAI NAT / PAI GF30 / PAI CF30 / PAI ESD

Yellow, Bronze

Rod Material

Specifications (Unit mm)| Outer diameter | length | 2.38⌀ / 3.18⌀ / 6.35⌀ / 9.53⌀ / 12.7⌀ / 15.88⌀ / 19.05⌀ / 25.4⌀ / 31.75⌀ / 34.93⌀ / 38.1⌀ / 50.8⌀ | 2,440 |

|---|

Board Material

Specifications (Unit mm)| thickness | width | length | 6.35T~31.75 T | 305 | 1,220 |

|---|